Process Technologies

“EXCESS METHANOL (SILVER CATALYST) PROCESS”

FOR

FORMALDEHYDE MANUFACTURE

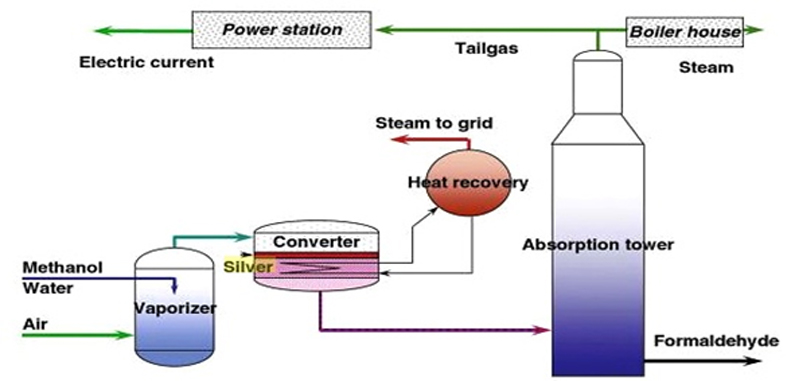

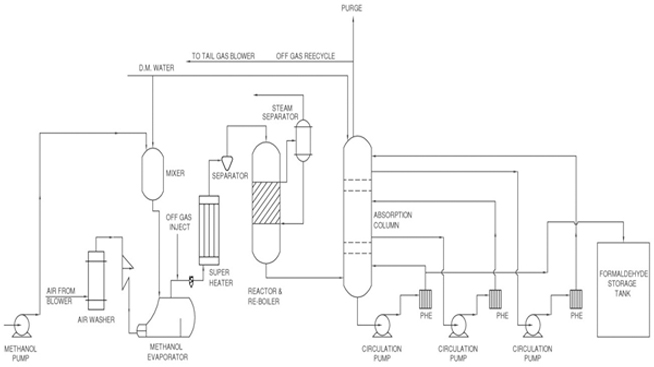

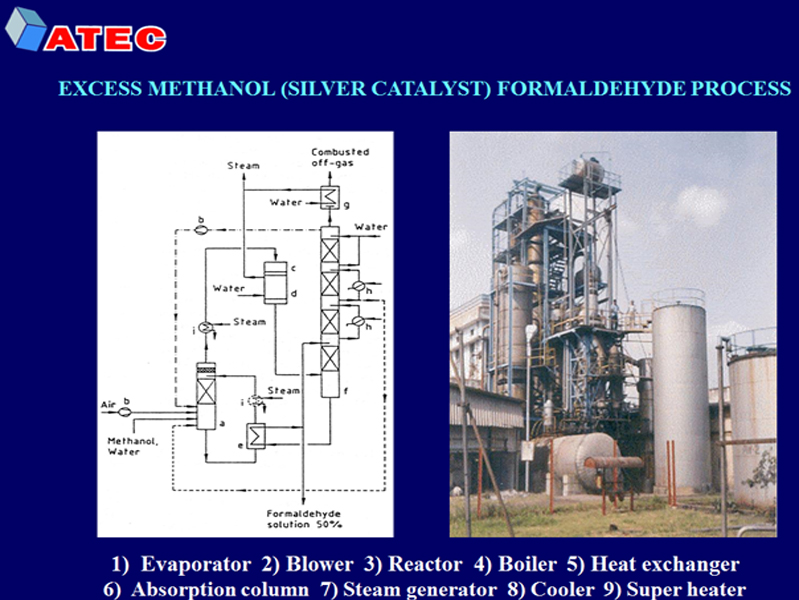

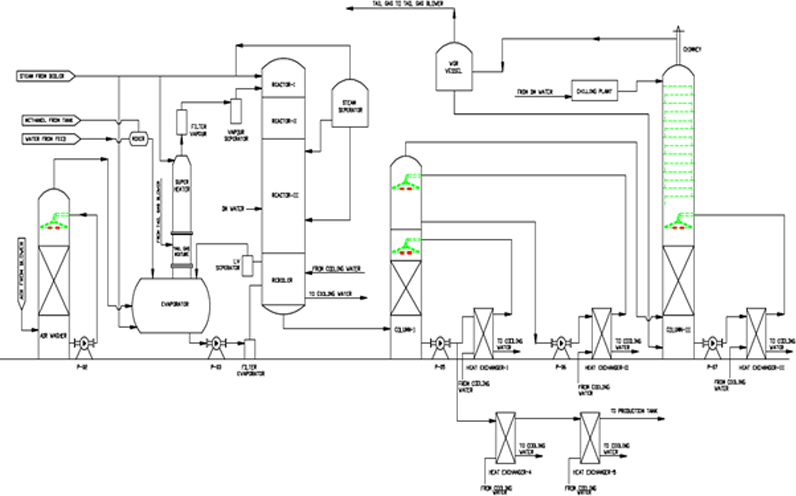

ATEC also offers a highly optimized “State of the Art Technology” based “Excess Methanol (Silver Catalyst) Process” for Aqueous Formaldehyde (AF-37) manufacture. The process is suitable for downstream production of Amino (UF / MF) Resins. Plants based on this process are relatively cheaper. Typical block / flow diagrams of the process are shown below :

“EXCESS METHANOL (SILVER CATALYST) FORMALDEHYDE PLANT PROCESS”

ATEC has a General Licensing Agreement with

M/S Aldehydes India (AI) for

“Excess Methanol (Silver Catalyst) Process Technology”.

Choice of an appropriate Catalyst for facilitating Oxidation of Methanol in the Formaldehyde Reactor is of paramount importance from the stand point of smooth trouble free long term operation of Plants.

ATEC recommends the use of Low Bulk Density Silver with purity of 99.99% having average Bulk Density of 2.2 Gms / Cubic Centimeter. The typical lifetime of this catalyst varies from 4 to 6 months.

SILVER CATALYST PROCESS BASED FORMALDEHYDE PLANTS

PRODUCT (AF-37) SPECIFICATIONS FOR SILVER CATALYST PROCESS

| Formaldehyde | : | 37% - 48% |

| Methanol content | : | 1.0% - 2.0% |

| pH | : | 3.5 - 4.0 |

| Iron | : | 2.0-PPM Max. |

| Ash | : | 0.01% Max. |

The modern

“Off - Gas Recycle System” for the Silver Catalyst Process has also been perfected by ATEC / AI and offered based on customer requirements.

SILVER CATALYST PROCESS WITH OFF – GAS RECYCLE SYSTEM

/h3>