Process Technologies

“EXCESS AIR (METAL OXIDE CATALYST) PROCESS” FOR

FORMALDEHYDE MANUFACTURE

AQUEOUS FORMALDEHYDE SOLUTIONS (AF-37 / AF-55) & UREA FORMALDEHYDE CONCENTRATE (UFC-85) PRODUCTION

Complete technical Know-How and design / engineering for

AF-37 / AF-55 Plants in the capacity range

(67 MTPD-400 MTPD) or equivalent Urea Formaldehyde Concentrate

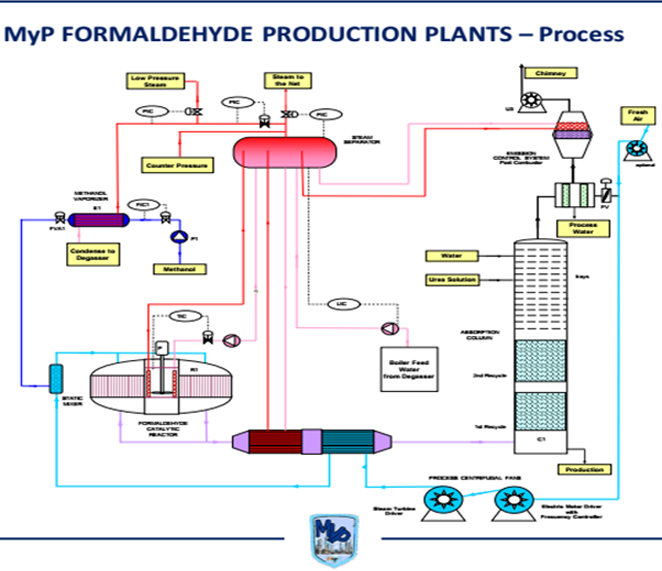

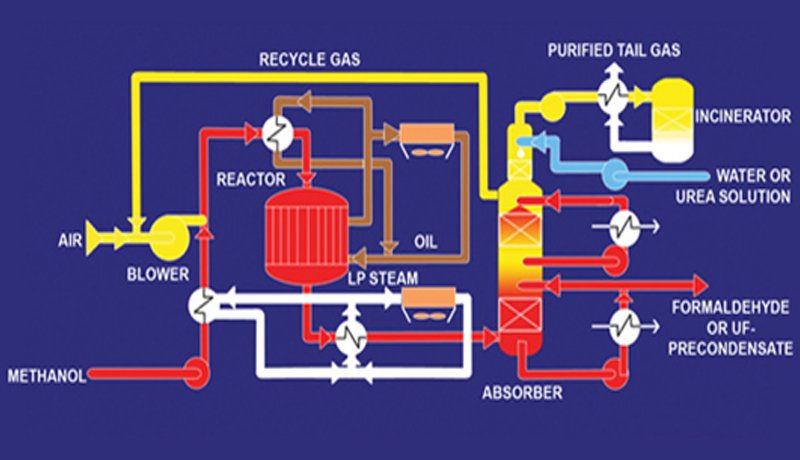

(UFC-85) based on Excess Air (Iron Oxide Catalyst) process can be provided. Formaldehydes are produced by Catalytic Oxidation of Methanol. A basic process flow diagram is shown below:

EXCESS AIR PROCESS FOR FORMALDEHYDE

As mentioned

ATEC has a

“General Licensing Agreement” with the renowned International Licensor

M/S HaldorTopsoe A/S (Denmark) for the

“Excess Air (Metal Oxide Catalyst) Process”

for production of Formaldehyde products. The Company has improved upon and developed

cutting edge “State of Art” technologies

for the Metal OxideFormaldehyde manufacturing processes based on decades of experience.

HALDOR TOPSOE / ATEC GENERAL LICENSING AGREEMENT FOR FORMALDEHYDE TECHNOLOGY

ATEC’s

preferred Formaldehyde Technology for simultaneous / individual production of

AF – 37 /AF-47/ AF – 55 and / or UFC-65 upto UFC-85 is based on the modern

“Excess Air Process of Formaldehyde manufacture”

commonly known as the

Metal Oxide Process.

ATEC uses its unique

“3D CAD Modelling Programs” for precise and highly optimized detailed engineering

of Excess Air (Metal Oxide Catalyst) Process as can be seen from the

Plant model and

actually built Plant (simultaneous AF-37 / UFC-85 production) photographs shown below :

AQUEOUS FORMALDEHYDE (AF-37 / AF-55)

Aq. Formaldehyde (i.e. 37% or 55% concentration Formaldehyde with varying stabilizing Methanol content (0.40 % to 12 %) finds end use applications in lamination industry, intermediate chemical for Oil field formulations, raw material for Insulation / Fiberglass industry, Fumigant for Poultry Farms, basic chemical for Synthetic Resins, Moulding Compounds, Powdered & liquid Resins, Organic dyestuff, Explosives, Soil disinfection chemicals, Pharmaceuticals, Inorganic Synthesis, Leather and Fur industries, Metal working industries, Paper processing, Rubber industry, Textile industry, Water Treatment industry, Sugar industry, Photographic Chemicals, Foundry moulds, embalming fluids & Preservatives.

AF-37 / AF-55 PLANT

PRODUCT SPECIFICATIONS FOR FORMALDEHYDE (AF-37 / AF-55 )

| Component |

Composition, wt% |

| Formaldehyde (HCHO) |

37.00 – 55.00 |

| Methanol (CH3OH) |

<1.0 |

| Formic Acid (HCOOH)

|

<0.05 |

| Water (H2O) |

Balance |

AF-37 / AF-55 TOPSOE FORMALDEHYDE PLANTS

ALTERNATIVE “EXCESS AIR (METAL OXIDE CATALYST) PROCESS” FOR FORMALDEHYDE MANUFACTURE – ATEC / MyP (ITALY) TIE-UP

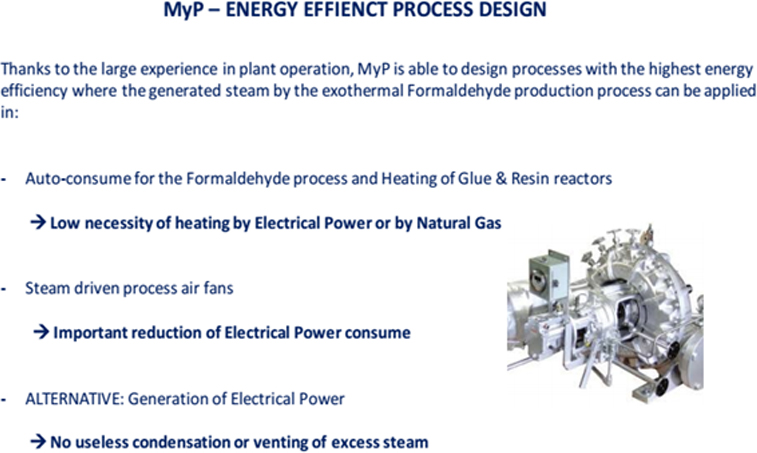

ATEC has also entered into a technical collaboration Agreement in the field of advanced technologies

including the

“Excess Air (Metal Oxide Catalyst) Process”.

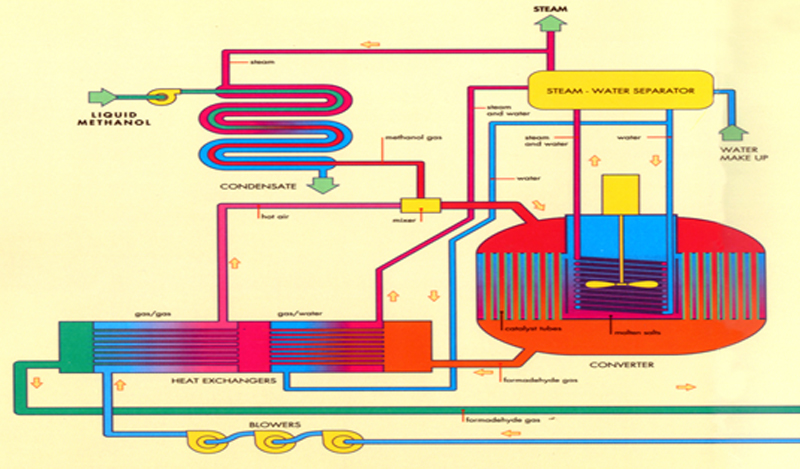

MyP PROCESS : MOLTEN SALT COOLED REACTOR