HYDROCARBON

CONVERSION PROCESSES

ATEC

provides Technological solutions for

setting-up key Process Plants based

on Hydrocarbon feedstocks viz. Natural

Gas / Naphtha.

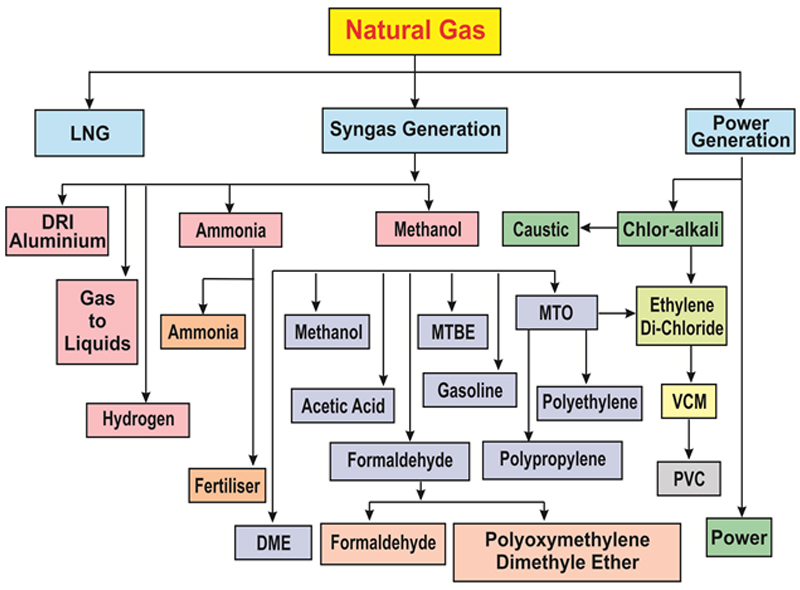

A “Natural

Gas Value Chain” diagram is shown below :

NATURAL

GAS VALUE CHAIN

ATEC’s

specialization basically encompasses the

following Natural Gas Derivatives Processes.

AMMONIA

/ UREA PRODUCTION PROCESSES

ATEC

can provide design / engineering services related to catalytic and non

catalytic conversion of Hydrocarbon feed stocks viz. Natural gas, Associated

gas, Shale gas, Coal Bed Methane, Petroleum Coke, Coal, Coke Oven gas and

Refinery Off gases.

Tailor made design for individual units of Ammonia

plants, Methanol Plants, and Urea plants are available including :

Primary Reformers

Shift Converters

Synthesis Loops

Hydrolyser Strippers

High performance Carbamate Condensers

T.

Bajpai has specialised in design / engineering

of Primary Reformers for any Ammonia / Methanol Plant capacity.

REFORMER UNITS

ATEC

can recommend appropriate “State of the

Art Hydrocarbon Processing technologies” for specific projects and provide Technology Availment services.

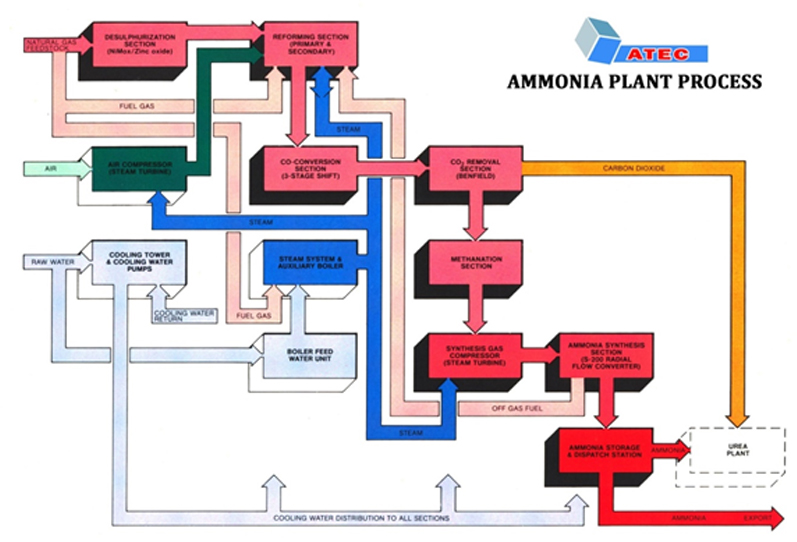

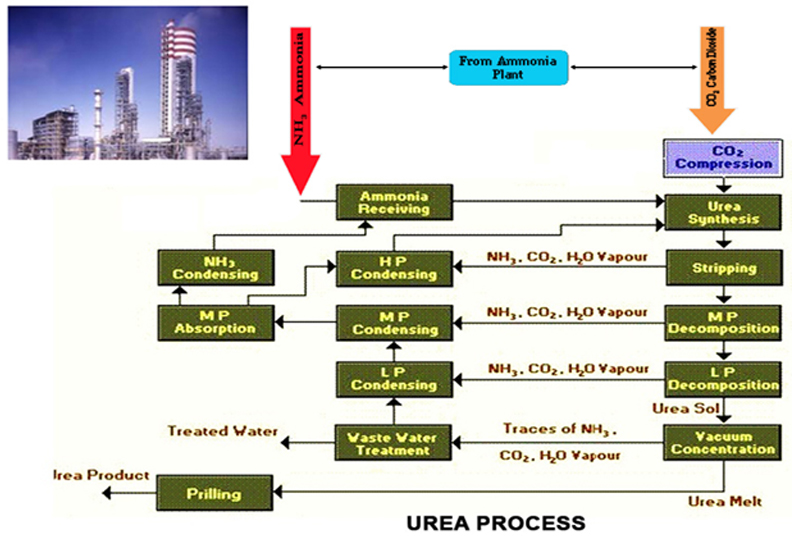

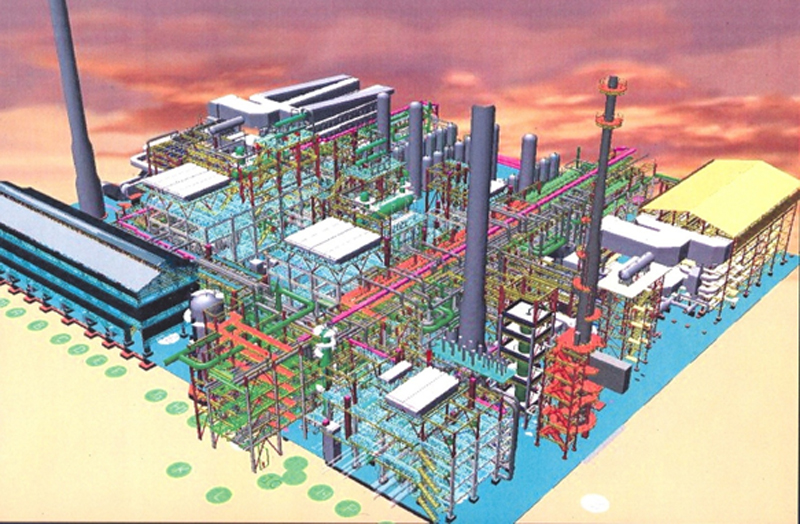

Representative basic flow diagrams of typical

Hydrocarbon feedstock based Ammonia and Urea Process Layouts are shown below.

Highly optimized Technological Process options targeting minimal specific

calorific consumptions can be provided suiting specific customer requirements.

For Urea

Plants both “Ammonia Stripping” and “Carbon-Di-Oxide Stripping” Process

Options can be provided.

METHANOL PRODUCTION PROCESSES

ATEC specializes in providing Technology Availment services for

Hydrocarbon feedstock based Methanol

Production Processes based on optimized

Process Layouts of proven design capable of rendering sustained troublefree

operations with low energy

consumptions.

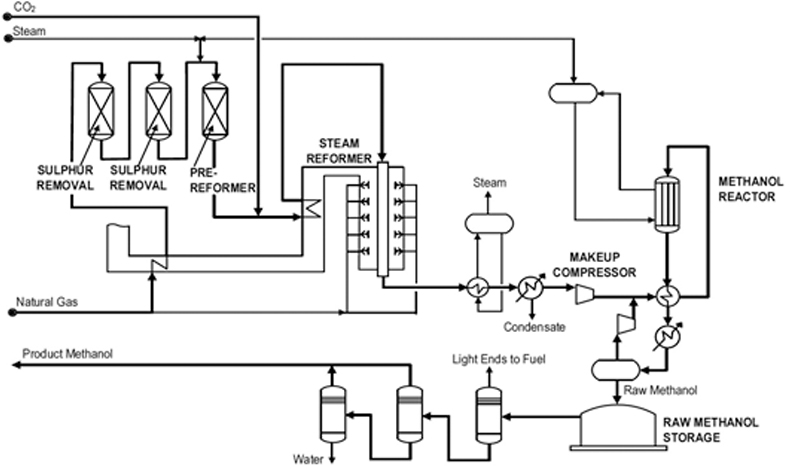

SCHEMATIC

DIAGRAM OF METHANOL PROCESS PLANT

M/S

HaldorTopsoe (Denmark) have perfected a “State

of the Art” Technology for Methanol production based on decades of experience

which is being continuously upgraded for modern day large scale capacity Plants

yielding minimum possible specific calorific consumption.

ATEC’s

preferred Technological solution for

Methanol Plants is to offer the Topsoe

Technology.

TOPSOE REFORMERS FOR

METHANOL PLANTS

A representative basic flow diagram of the Topsoe

Methanol Process is shown below :

METHANOL PRODUCTION

PROCESS

METHANOL PRODUCTION

PROCESS

METHANOL

PLANT

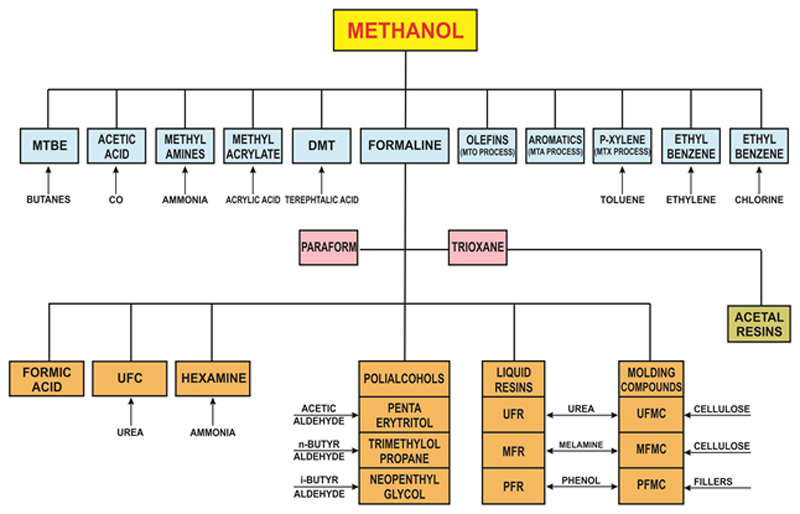

METHANOL DERIVATIVES’ PROCESSES

ATEC offers highly optimized Process

solutions for a majority of Methanol Derivative products, specifically in the

domain of Formaldehyde and its value added derivatives :

METHANOL VALUE CHAIN

FORMALDEHYDE DERIVATIVES COMPLEX