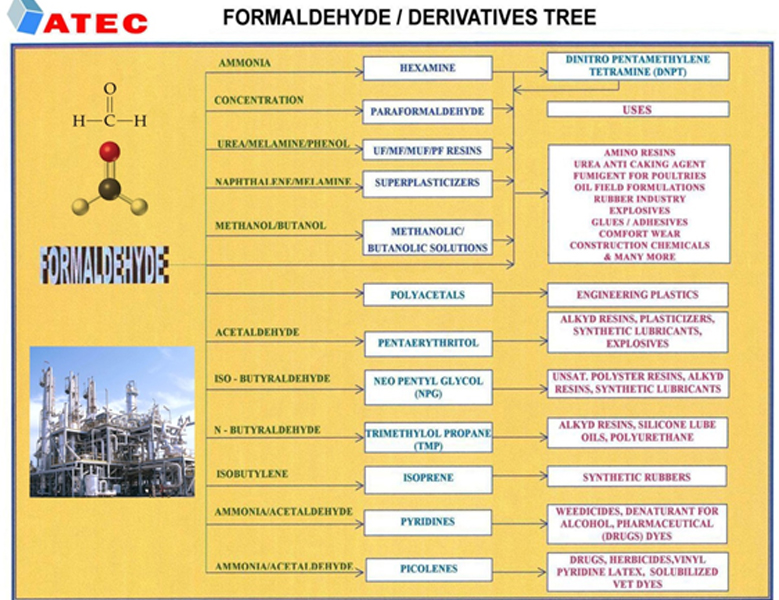

FORMALDEHYDE / DERIVATIVES

PROCESSES

ATEC’s core expertise is in the domain of

the entire gamut of Formaldehyde /

Derivatives Processes briefly outlined in the “Formaldehyde

Tree” presented below :

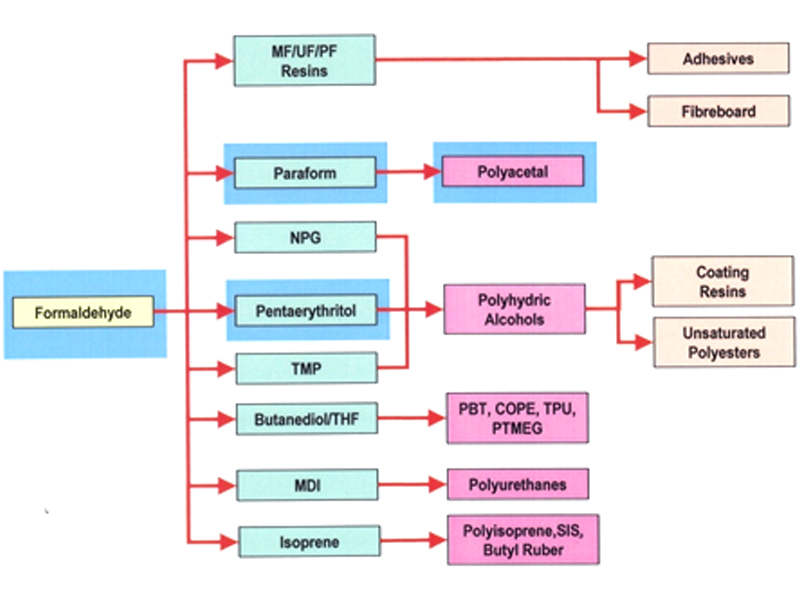

OVERVIEW – FORMALDEHYDE VALUE CHAIN

ATEC`s FORMALDEHYDE /

DERIVATIVES TECHNOLOGIES – TECHNOLOGICAL OVERVIEW

ATEC possesses both the commonly known Technologies

for manufacture of Formaldehyde Products i.e.:

·

Excess Air

(Metal Oxide Catalyst) Process

·

Excess Methanol

(Silver Catalyst) Process

However currently the modern excess air process of

Formaldehyde manufacture commonly known as the Metal Oxide process is in vogue

owing to multiple operational advantage

afforded by the same.

Moreover ATEC has in – house“Cutting Edge manufacturingtechnological know – howandState

of the Artengineering expertise” to build plants to produce most of the Formaldehyde

derivatives as well. The range of Formaldehyde / derivatives

technologies offered include :

a.

Hexa

Methylene Tetra Amine (H.M.T. / HEXAMINE)

b.

Paraformaldehyde

c.

Urea

Formaldehyde (UF) Amino Resins

d.

Melamine

Formaldehyde (MF) Amino Resins

e.

Urea –

Melamine Formaldehyde (MUF) Combination Amino Resins

a.

Pre-catalyzed

Amino Resins

b.

Resol

Phenolic Resins

c.

Novolac

Phenolic Resins

d.

Sulphonated

Naphthalene Formaldehyde (SNF / PNS) Superplasticizers

e.

Sulphonated

Melamine Formaldehyde (SMF / PMS) Superplasticizers

f.

Methanolic

Solutions of Formaldehyde

g.

Butanolic

Solutions of Formaldehyde

h.

Pentaerythritol

FORMALDEHYDE COMPLEX