ATEC’s PARAFORMALDEHYDE

TECHNOLOGIES

ATEC is in

possession of technologies to produce all

types of Paraformaldehyde products in varying concentration ranges and

polymerization degree spans. It can offer PLANTS for:

(89-91)%

FLAKED PARAFORMALDEHYDE PRODUCTION

Multi stage evaporation

and chilled conveying process.

(91-96)%

GRANULAR / PRILLED PARAFORMALDEHYDE PRODUCTION

Multi stage evaporation

and rotary vacuum drying.

(91-96)%

PRILLED PARAFORMALDEHYDE PRODUCTION

Multi stage evaporation

and spray cum fluidized bed drying.

PARAFORMALDEHYDE PLANTS

PLANTS

for production of flakes are relatively inexpensive, whereas the processes for

production of prills / granules are

fairly elaborate and such PLANTS involve a much larger investment.

Paraformaldehyde

is a polymer of Formaldehyde in solid form, containing a percentage of

water, readily soluble in order to obtain an aqueous solution or to be used as

a reactant by dissolving it in the reaction medium.

Paraformaldehyde,

which is represented by typical formula HO

(CH2O)n H is

also termed as mixture of Polyoxymethylene Glycols. It is controlled polymerized product of

Formaldehyde in solid form. The presence

of Formaldehyde unit per molecule is more than 6.

PARAFORMALDEHYDE

PRODUCTS RANGE

Typical characteristics of various Paraformaldehyde

grades known to be manufactured are given below:

|

FREE

FLOWING WHITE GRANULES WITH TYPICAL FORMALDEHYDE ODOUR (Granules)

|

WHITE

POWDER

|

|

89%

|

91%

|

93%

|

96%

|

97%

|

|

FORMALDEHYDE

CONTANT (%)

|

|

89

± 1

|

91

± 1

|

93

± 1

|

95.5

± 1

|

96.5 ± 1

|

|

METHANOL

CONTENT (%Max.)

|

|

1

|

0.5

|

0.5

|

0.5

|

0.5

|

|

pH (10%

AQUEOUS SUSPENSION

|

|

3-5

|

3.5-6.5

|

3.5-6.5

|

5-7

|

5-7

|

|

ACIDITY (AS

FORMIC ACID (%) Max.)

|

|

0.03

|

0.03

|

0.03

|

0.03

|

0.03

|

|

REACTIVITY

(RESORCINOL TEST ) (Minutes)

|

|

2-3

|

2-4

|

2-4

|

2-4

|

3-5

|

|

FLASH POINT

(OPEN CUP) (oC)

|

|

93

|

93

|

93

|

93

|

93

|

|

FLASH POINT

(CLOSED CUP) (oC)

|

|

71

|

71

|

71

|

71

|

71

|

|

IRON CONTENT

(PPM Max.)

|

|

2

|

2

|

2

|

2

|

2

|

|

ASH CONTENT

(PPM Max.)

|

|

100

|

100

|

100

|

100

|

100

|

|

MELTING POINT

(oC)

|

|

120-170

|

120-170

|

120-170

|

120-170

|

120-170

|

|

BULK DENSITY

(kg / m3)

|

|

750-750

|

750-850

|

750-850

|

750-850

|

500-800

|

|

GRAIN SIZE

(MIN. 80%) (mm)

|

|

|

|

0.2-1.0

|

0.2-1.0

|

0.2-1.0

|

0.2-1.0

|

Min. 90% < 0.100 DIN 60

|

PRODUCTION TECHNIQUE

Production of Paraformaldehyde usually starts

from 37% or 55% by weight aqueous

solutions of Formaldehyde. It is concentrated at temperatures below 100°C often

done by vacuum distillation and mainly water distills of at first. The

concentration of Formaldehyde present chiefly as hydrate is increased. The

solutions can be concentrated in this way up to Formaldehyde content of above

80% at which point the greater part of the Formaldehyde is already present in

the form of oligo – oxymethylene glycols. On cooling, gels with colloidal

properties are obtained which are at first waxy but later on becomes brittle

which consist of Paraformaldehyde.

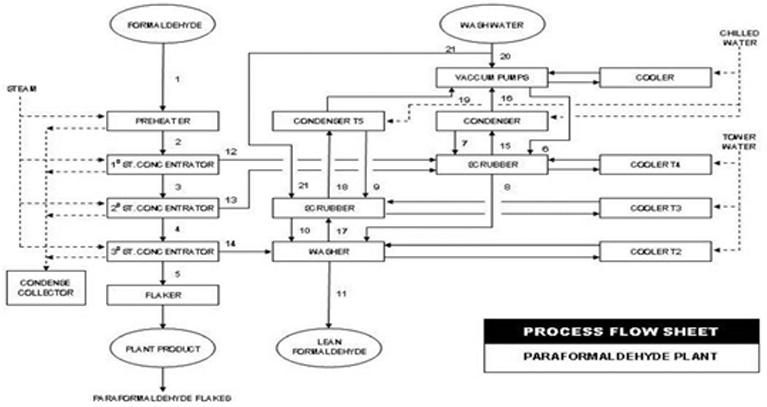

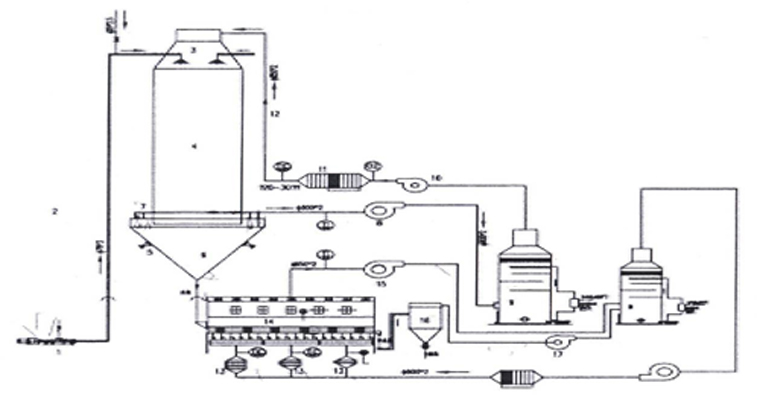

ATEC`s FLAKED

PARAFORMALDEHYDE TECHNOLOGY

Paraformaldehyde in

flake form is produced by this process.

The raw material for the said Paraformaldehyde production is freshly

manufactured high concentration (52-55%) Formaldehyde solution. A basic flow

diagram is given below :

Salient

Features

Salient features of ATEC`s modified process for

manufacture of flaked Paraformaldehyde are enumerated below:

1)

Simple in Operation

2)

Free flowing, dustless

white flakes. Dust is a big problem for the workers handling Para

3)

100% utilization of

Formaldehyde with almost ‘0%’ loss in the process.

4)

100% pollution free

5)

Highest safety measures

6)

Easy solubility and

simple to dissolve

7)

Low power consumption

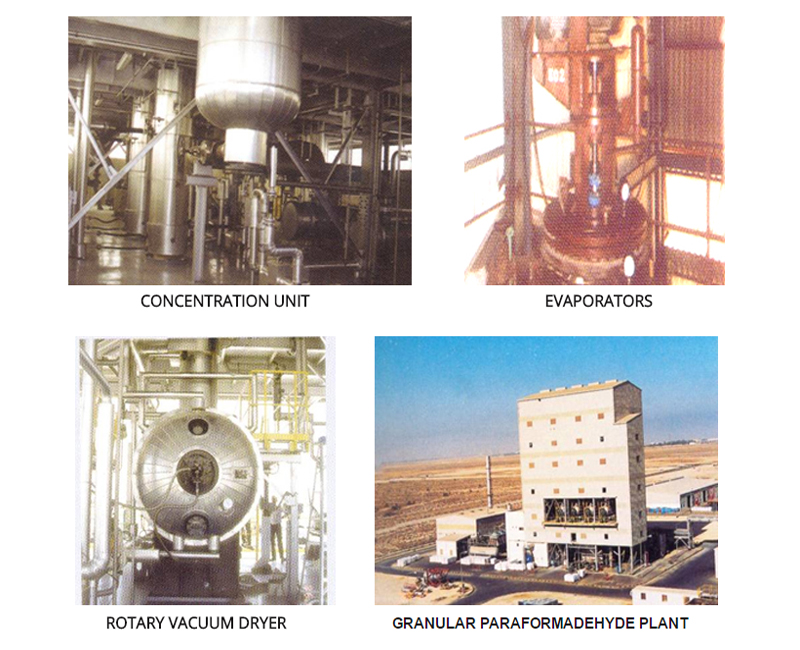

FLAKED

PARAFORMALDEHYDE PLANTS

GRANULAR

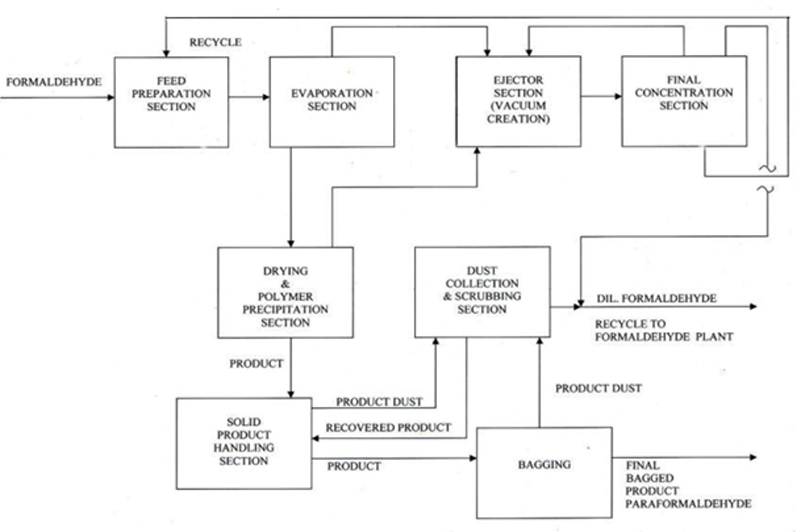

/ PRILLED PARAFORMALDEHYDE PRODUCTION TECHNOLOGY BY ROTARY VACUUM DRYING

A unique process based on Vacuum Concentrated and Drying of Product

to produce various (91% to 96%) concentration grades of Paraformaldehyde would

be applied. In the ATEC process Paraformaldehyde is manufactured from aqueous

(37%) Formaldehyde solutions by the process involving distillation and

concentration at a point at which solidification or precipitation of polymer

takes place. The process of concentration is carried out by vacuum evaporation.

The main sections of the PLANT are:

Concentration of aqueous

Formaldehyde (AF-37 / AF-55)

Polymerization and

drying

Concentration of

distillates for recycling.

Conveying,

pulverization and storage / packaging of the Product.

This Process is offered by ATEC in association with Libra Techcon.

Indicative Process flow diagram for the Granular / Prilled Paraformaldehyde

processes is shown below:

GRANULAR / PRILLED PARAFORMALDEHYDE PROCESSES BASED ON ROTARY VACUUM DRYING

The Process has been over the years upgraded based on actual operational experience obtained in

PLANTS of different optimal production level from 5 M.P.D through 15 M.T.P.D.

upto 30 M.T.P.D. and beyond. The upgradation carried out was in terms of optimization

of equipment / machinery sizing and more compact lay out at individual floor

level of the PLANTS.

PARAFORMALDEHYDE PLANTS

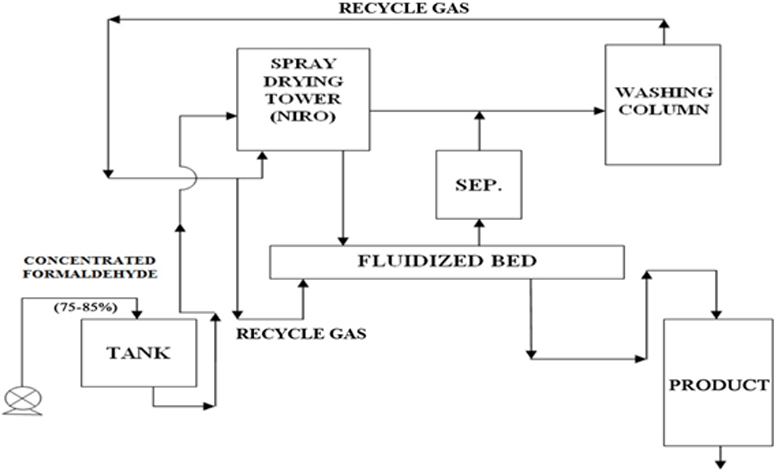

PRILLED

PARAFORMALDEHYDE PRODUCTION PROCESS BASED ON SPRAY CUM FLUIDIZED BED DRYING

The process essentially consists of the following

steps:

·

Concentration of

Aqueous Formaldehyde

·

Vacuum Spray Drying

·

Fluidized Bed Drying

·

Product Handling

Concentration of Aqueous

Formaldehyde (AF-37) to AF (75 – 85) is carried out in a falling film

evaporation and thin film evaporation (side stream) system.

(75 – 85) % concentrated Aqueous

Formaldehyde is fed to a conical bottom NIRO vacuum Spray Dryer.

Spray dried powder is further

concentrated in a Fluidized Bed Dryer before being sent to the product handling

system. A liquid catalyst is used.

Three different grades (89%, 92%

and 96%) of Paraformaldehyde are produced by under for end use application in

resins, agro chemicals (Herbicides / Pesticides), Disinfectant / Medical

intermediates sectors.

Basic block diagrams of the Process

are shown below:

PROCESS

BLOCK DIAGRAM

ALTERNATIVE

PRILLED FORMALDEHYDE PROCESS

An alternative process for production of

prilled Paraformaldehyde products

using the “Prilling Tower Concept” is

also available. A schematic block

diagram of this Process is shown below:

SCHEMATICS

OF PRILLED PARAFORMALDEHYDE PRODUCTION

COMBINED

SPRAY AND FLUIDIZED BED DRYING FOR PARAFORM

PRODUCT’S

SPECIFICATIONS

The granular Paraformaldehyde manufacturing processes offered by ATEC

will produce Paraformaldehyde of the

following specifications:

|

Aldehyde

content (as HCHO % by mass)

|

:

|

(91-96

± 1) for individual grades

|

|

Ash

Content, ppm (max.)

|

:

|

100

|

|

Free

Moisture content Percent by mass, (max.)

|

:

|

1

|

|

Acidity

(as HCOOH) Percent by mass (max.)

|

:

|

0.03

|

|

Iron

(ppm by mass max)

|

:

|

2

|

|

p-H

|

:

|

4

– 7

|

|

Methanol

(% by mass max.)

|

:

|

1

|

|

Melting

Point

|

:

|

120º

- 170º C

|