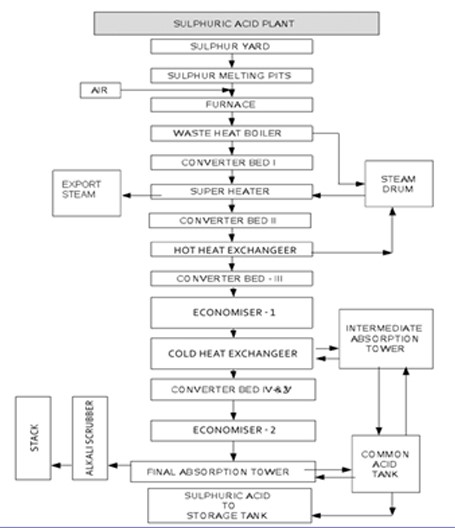

ATEC’s Sulphuric Acid Process Technology (in association with collaborators) is based on the Double Conversion Double Absorption (DCDA) contact process. It consists of three principal steps:

S + O2 → SO2

SO2 + ½ O2 → SO3

SO3 + H2O → H2SO4

| Sulphuric acid specification | Unit | Lower specification limit |

Upper specification limit |

|

|---|---|---|---|---|

| SULPHURIC ACID (Technical grade) IS 266-1993 |

Specific gravity | gm/ml | 1.82 | |

| Purity | % by wt. | 98 | ||

| Residue on ignition | % by wt. | 0.05 | ||

| Iron as Fe₂O₃ | ppm | 100 | ||

| Heavy metals as Pb | ppm | 50 | ||

| Arsenic as As | ppm | 40 | ||

The advantage of this Technology is that much better SO2 to SO3 conversion efficiencies are obtained due to intermediate absorption, since the ‘product’ formed i.e. SO3 has been removed and so the reaction tends to proceed more towards the product side. It is possible to get conversion efficiencies up to 99.8% compared to about 98% of earlier single absorption technology. Such high conversion efficiencies naturally result in lower SO2 emissions to the environment from the process.