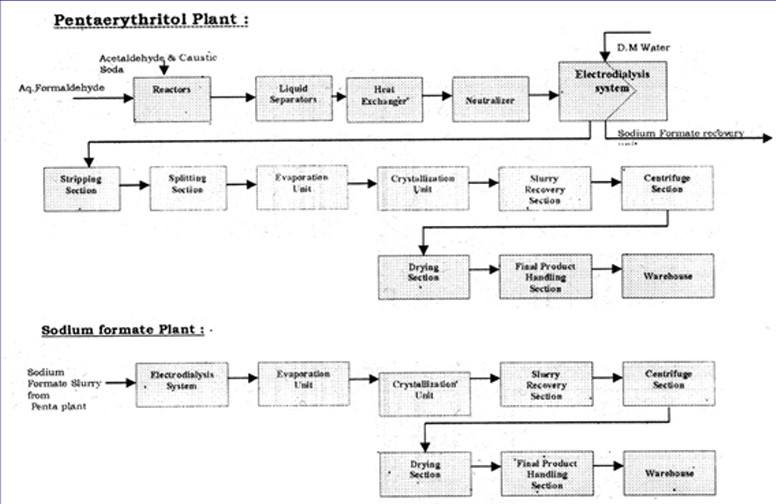

PENTAERYTHRITOL or PE is a tetrahydric alcohol which has found widespread use in the Resin, Plastics, Lubricants and Explosive industries.

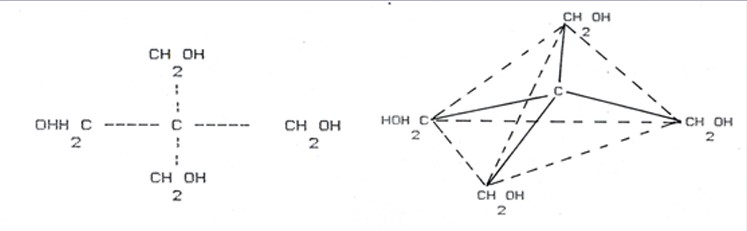

It is a white crystalline solid which has four methylol groups arranged symmetrically around a central carbon atom as shown in the structural formula below:

| PROPERTY | SPECIFICATIONS |

|---|---|

| Appearance | White coarse free flowing |

| Monopentaerythritol content (Wt % Min.) | 98 |

| Hydroxyl number (Mg KOH/g) | 1625 – 1650 |

| Melting Point (Min. degree C) | 257 |

| Moisture content (Wt % Max.) | 0.1 |

| Ash content as Na (PPM Max.) | 15 |

| Colour as Phthalate (Gardner Max.) | 1.4 |

| Melting point (water–free salt) | 255°c |

| Melting Heat | 244.5 kJ/Kg |

| Specific Heat | 1.21 kJ/Kg K |

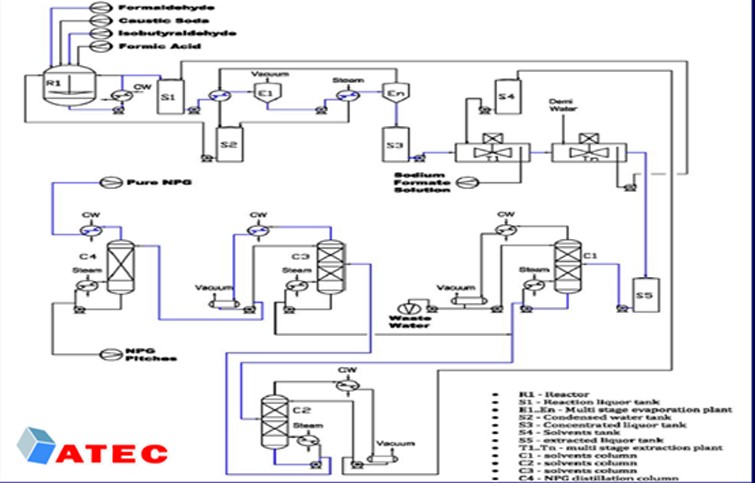

ATEC offers the “State of the Art” Process Technology for production of Neo Pentyl Glycol (NPG) under a special licensing Agreement with a renowned European licensor.

| Characteristics | Standard Limit |

|---|---|

| Purity | 99% min |

| Hydroxyl number | 1065 mg KOH/g min |

| Acidity number | 0.1 mg KOH/g max |

| Colour (APHA) | max 15 mg Pt/l |

| Water (molten product) | 0.3% max |

| Solidification point | 124 to 130°C |

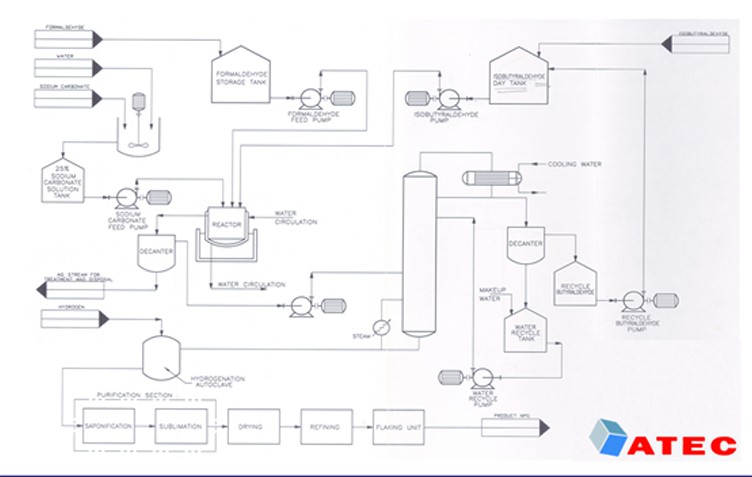

Tri Methylol Propane (T.M.P.) is a type of Polyhydric Alcohol, resulting from mixed Aldol Condensation reaction between Formaldehyde and Acetaldehyde, Isobutyraldehyde and Butyraldehyde. Initially an Aldehydic intermediate is formed which must be reduced to Polyhydric Alcohol.

TMP is produced by reaction of Butyraldehyde, Formaldehyde and a base Sodium Hydroxide in aqueous medium. The reaction takes place according to the following equation:

Sodium Formate equivalent to each mole of TMP is produced as a byproduct. Finally the excess alkali is neutralized with Formic Acid and the pH is brought down to 6.8 and unreacted Formaldehyde is distilled off and this is followed by recovery of Tri Methylol Propane from the residual solution. The reaction is vigorous and the reaction temperature is maintained between 50–60°C. The rise of temperature is about 30°C.

TMP is recovered by extraction with Ethyl Acetate. The extract is distilled to evaporate the solvent and any water. The residue from this distillate is crude TMP containing minor amounts of less volatile impurities. Crude TMP is purified by vacuum distillation of this product at 142°C and 3 mm Hg absolute pressure.