M/S HALDOR TOPSOE A/S (DENMARK)

M/S SADEPAN CHIMICA NV (ITALY)

M/S ARCL ORGANICS LIMITED (INDIA)

M/S SMS MEER/ SIMAC (Italy)

M/S HYMMEN GMBH (Germany)

M/S VITS GMBH (Germany)

M/S SIMON CARVES/ SIMON INDIA (India)

M/S DE DIETRICH, FRANCE

M/S DIPESH ENIGINEERING MUMBAI, INDIA

M/S PRESSWELL FILTERS, BELGAUM, INDIA

M/S GMM PFAUDLER, KARAMSAD, INDIA

M/S SUPERFLOW PUMPS, MUMBAI, INDIA

M/S SWISS GLASSCOAT, ANAND, INDIA

M/S CHEMFILT, ANAND, INDIA

M/S COMP/ MOJJ ENGG., PUNE, INDIA

M/S INTRELEC, MUMBAI, INDIA

M/S ALFA LAVAL, PUNE, INDIA

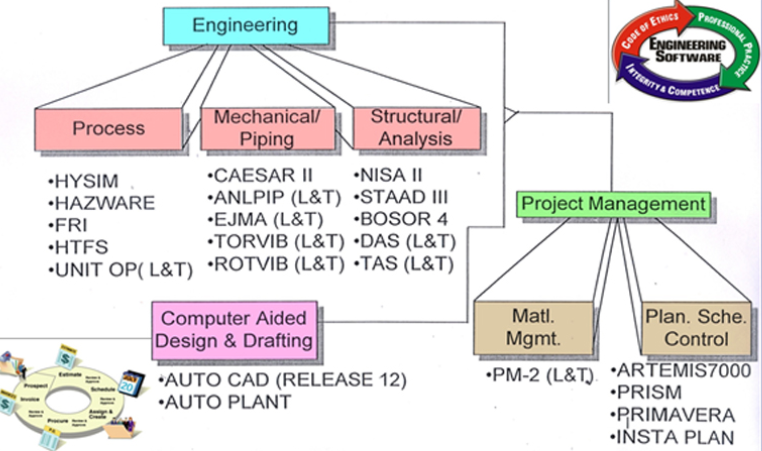

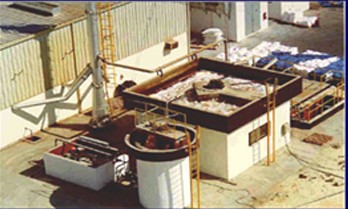

The company employs modern techniques of project management

to ensure timely and speedy execution of the projects. A team of

experts provide committed leadership and are closely associated

with the Co-ordination of individual projects, duly assisted by a

highly motivated team of projects managers and project engineers

planning engineers and cost engineers are associated with the

project Management team to monitor progress and provide cost

control system for the project.

Under an arrangement with several design/ engineering ATEC engineering services during

execution of projects, covering the following areas:

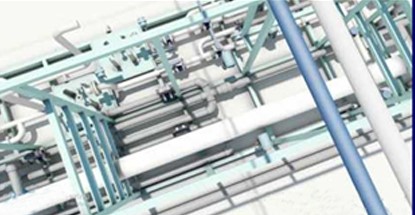

- Civil foundations

- Pre-Engineered and Rcc buildings

- Steel structures and pipe bridges

- Soil investigation and topography services

- Mechanical design of pressure vessels, heat exchangers, vessels,

coolers / condensers, reactors, absorption columns, driers and

other process equipment.

- Piping design and engineering

- Instrumentation and electrical design / engineering

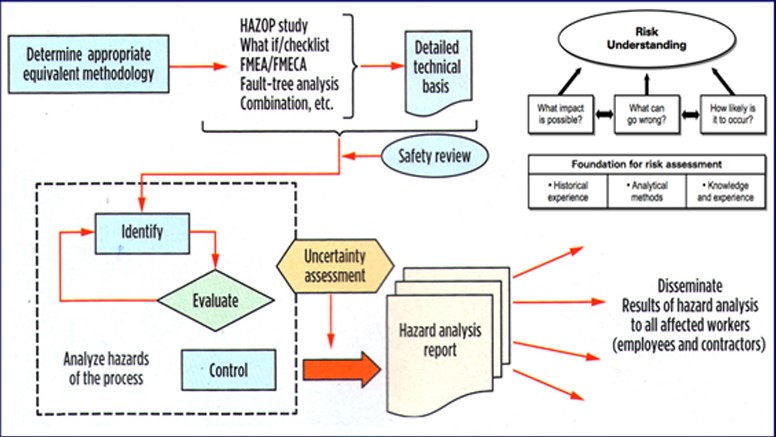

- Safety engineering

ATEC offers design and engineering services for catalytic and non-catalytic conversion of feedstocks like:

- Natural Gas

- Associated Gas

- Shale Gas

- Coal Bed Methane

- Petroleum Coke

- Coal, Coke Oven Gas, and Refinery Off-Gases

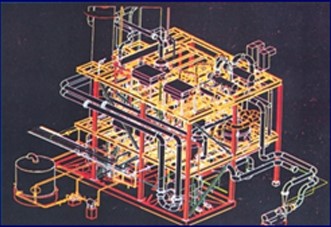

Tailor-made units available:

- Primary Reformers

- Shift Converters

- Synthesis Loops

- Hydrolyser Strippers

- Carbamate Condensers

ATEC ensures the most suitable and energy-efficient technology recommendations, offering either Ammonia Stripping or CO₂ Stripping urea process options.

Methanol Production Processes: M/S HaldorTopsoe (Denmark) have perfected a “State of the Art” Technology for Methanol production based on decades of experience which is being continuously upgraded for modern day large scale capacity Plants yielding minimum possible specific calorific consumption.

WHY THIS CONTENT IS NOT USED FROM WEB

ATEC’s preferred Technological solution for Methanol Plants is to offer the Topsoe Technology.

Features of Topsoe Methanol Technology:

- Proven technology with wide operating range, reliability and ease of operation.

- Reactor design and catalyst providing stable operation and excellent catalyst life.

- Low energy consumption due to low steam consumption and good heat recovery systems.

- Flexible operation and design allowing use of various feedstocks.

- Low emissions and environment friendly technology.

ATEC provides detailed process design, engineering, procurement, commissioning and start-up support services for Methanol Plants using Topsoe Technology.

ATEC also offers technological support for Methanol Derivatives Processes such as Formaldehyde, Dimethyl Ether and MTBE.

Natural Gas Value Chain – ATEC helps customers to design and implement the entire Natural Gas Value Chain, from gas gathering, treatment, processing, liquefaction, transportation to end use.

ATEC’s services cover all aspects of gas treatment, dehydration, fractionation, sweetening, liquefaction and regasification along with LNG storage and transportation infrastructure.