ATEC provides Technological solutions for setting-up key Process Plants based on Hydrocarbon feedstocks viz. Natural Gas / Naphtha.

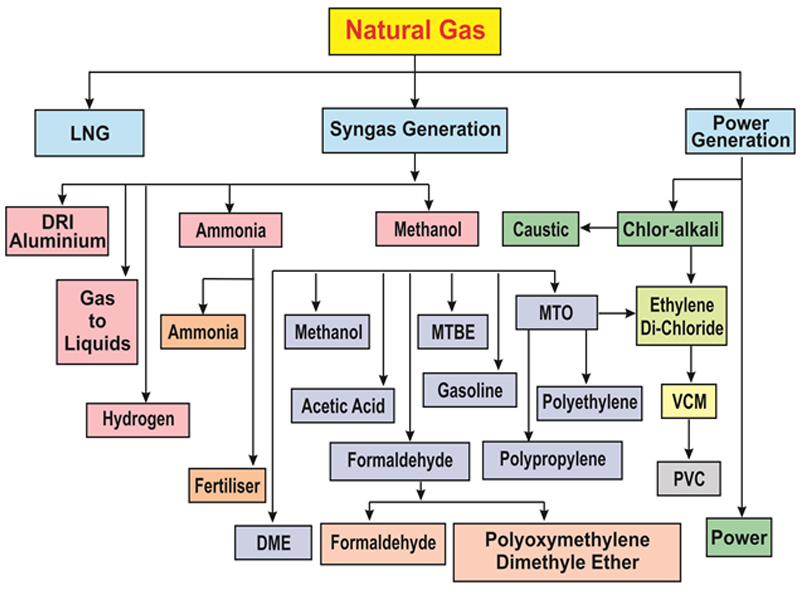

A “Natural Gas Value Chain” diagram is shown below :

ATEC’s specialization basically encompasses the following Natural Gas Derivatives Processes.

ATEC offers design and engineering services for catalytic and non-catalytic conversion of feedstocks like:

Tailor-made units available:

ATEC ensures the most suitable and energy-efficient technology recommendations, offering either Ammonia Stripping or CO₂ Stripping urea process options.

Methanol Production Processes: M/S HaldorTopsoe (Denmark) have perfected a “State of the Art” Technology for Methanol production based on decades of experience which is being continuously upgraded for modern day large scale capacity Plants yielding minimum possible specific calorific consumption.

WHY THIS CONTENT IS NOT USED FROM WEB

ATEC’s preferred Technological solution for Methanol Plants is to offer the Topsoe Technology.

Features of Topsoe Methanol Technology:

ATEC provides detailed process design, engineering, procurement, commissioning and start-up support services for Methanol Plants using Topsoe Technology.

ATEC also offers technological support for Methanol Derivatives Processes such as Formaldehyde, Dimethyl Ether and MTBE.

Natural Gas Value Chain – ATEC helps customers to design and implement the entire Natural Gas Value Chain, from gas gathering, treatment, processing, liquefaction, transportation to end use.

ATEC’s services cover all aspects of gas treatment, dehydration, fractionation, sweetening, liquefaction and regasification along with LNG storage and transportation infrastructure.