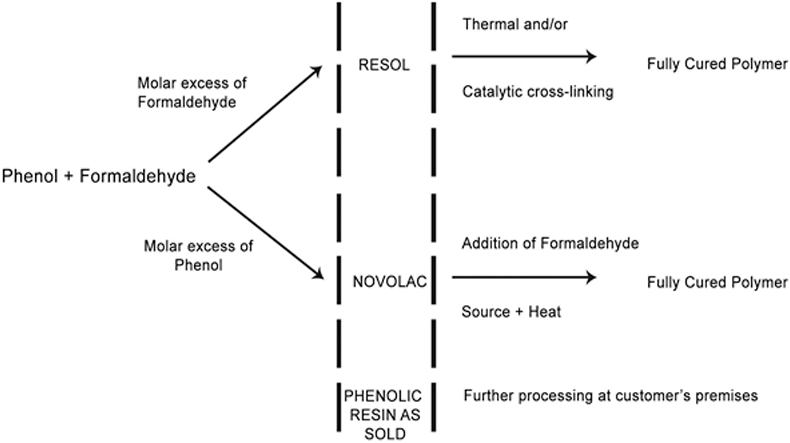

ATEC offers complete process know-how for production of both Resol and Novolac type Phenol Formaldehyde (PF) Resins.

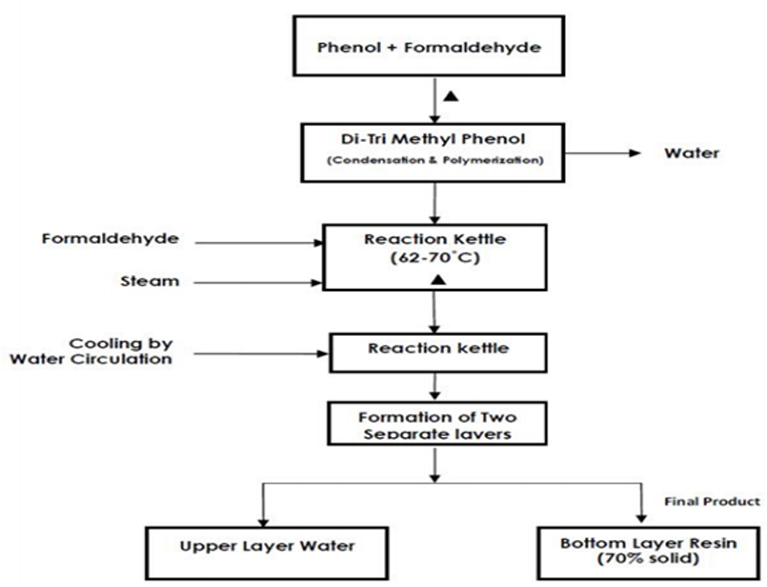

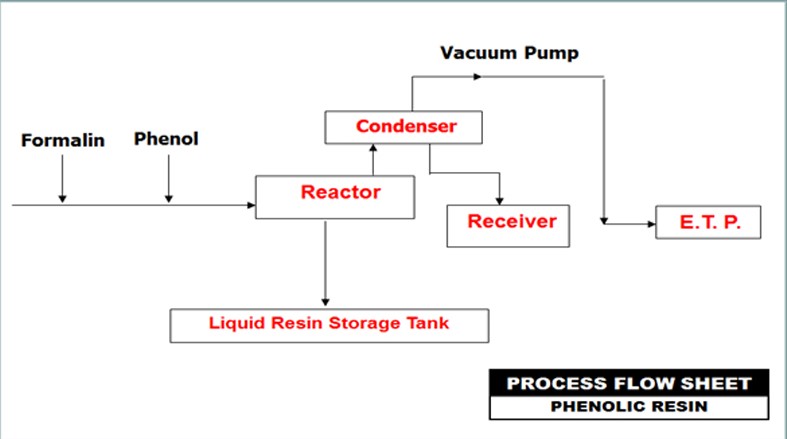

BASIC FLOW DIAGRAM OF ATEC’s PHENOLIC RESINS’ PROCESS

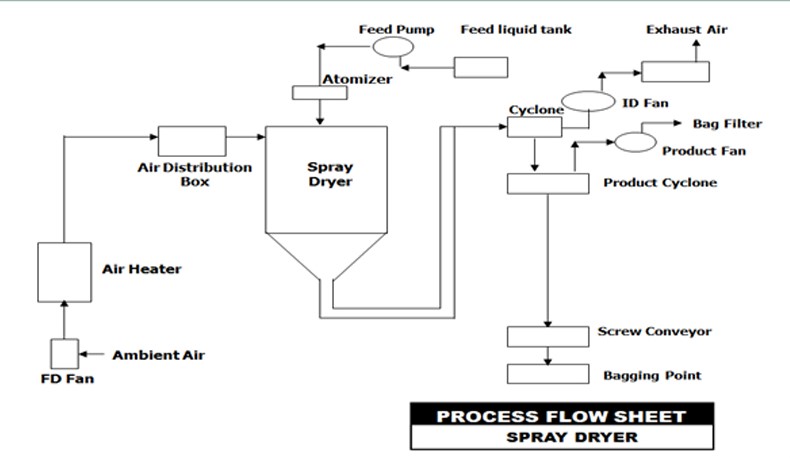

ATPFORM – 180 is a Phenol Formaldehyde Resol Resin Powder specially developed for Plywood / Chipboard / Flush Door manufacturing. It is suitable for the manufacture of Plywood conforming to various specifications. ATPFORM – 180 mixed with appropriate Hardner provides a Boiling Water proof adhesive for manufacture of exterior and marine grades Plywood as per IS 848, Type BWR & BWP.

| Appearance | Brown Free Flowing Powder |

|---|---|

| Bulk Density | 0.45 to 0.5 gms / cc |

| Viscosity (1:1 Solution) | 30 – 40 secs at 25°C in B4 cup |

| Viscosity (1:1 Solution) | 75 – 250 cps |

| Gel Time | 3 – 5 Mints at 140°C |

| Solubility | Easily soluble in cold water |

| pH (1:1 Solution) | 11.0 to 11.5 |

| Specific Gravity in 1:1 solution at 25°C | 1.22 to 1.23 |

ATEC’s ATPFORM – 810 Novolacs are Phenol-Formaldehyde resins with a Formaldehyde to Phenol molar ratio of less than one. The polymerization is brought to completion using acid-catalysis such as Oxalic Acid, Hydrochloric Acid or Sulfonate acids. The Phenol units are mainly linked by Methylene and/or Ether groups. Novolacs are commonly used as photoresists.

The molecular weights are in the low thousands, corresponding to about 10–20 phenol units. Hexamethylene Tetra Amine or "Hexamine" is a hardener added to crosslink Novolac. At a temperature >90 °C, it forms Methylene and Di-Methylene Amino bridges. Typical specifications of various grades of ATPFORM – 810 are tabulated below:

| Parameter | Unit | Type A | Type B | Type C | Type D |

|---|---|---|---|---|---|

| Type | - | Novolac | Novolac | Novolac | Novolac |

| Phenol:Formalin Ratio | - | 1:0.63 | 1:0.69 | 1:0.76 | 1:0.82 |

| Form | - | Flakes | Flakes | Flakes | Flakes |

| Melt Viscosity (at 175°C, Cone-Plate) | MPa | 80-150 | 210-350 | 700-1100 | 3000-4000 |

| Flow Length (at 125°C) | mm | 120-190 | 110-150 | 100-150 | 90-150 |

| Melting Point | °C | 72-80 | 78-85 | 80-95 | 90-105 |

| Free Phenol | % | Less Than 1 | Less Than 1 | Less Than 1 | Less Than 1 |