ATEC offers the entire range of “State of Art” process technologies for production of Hexa Methylene Tetra Amine (H.M.T. / HEXAMINE) products and provides complete technological Know-How and design /engineering of hexamine plants (5 MTPD to 30 MTPD Capacity) in association with M/S Libra Techcon (LTL).

ATEC possesses the complete technological know-how and basic design / detailed engineering expertise to build Hexamine Plants based on both Liquid Phase Ammoniation and Vapour Phase Ammoniation variants of the manufacturing process.

“Hexamine” (produced by reaction between Ammonia and Aqueous Formaldehyde) is the short form of Hexa Methylene Tetra Amine (C6H12N4). It also has other names like Urotropin, Methenamine, Aminoform, Crystamin, Formin, Uritone etc.

Hexamine is a solid crystalline or granular white powder generally having an average particle size of 40 to 60 meshes per linear inch. It is soluble in water, spirit, chloroform etc.

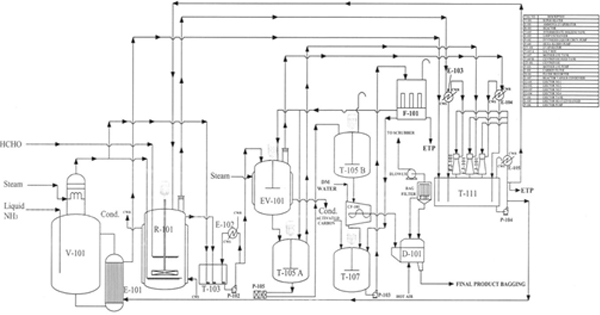

Hexamine is the amino – analogue of Trioxane. In the liquid phase process Hexamine is produced by reaction of Aqueous Formaldehyde (AF 37) and anhydrous Ammonia in liquid forms. In a slightly different process vapour phase Ammoniation of Formaldehyde can also be carried out. A basic flow diagram is given below:

Two different grades of Hexamine are generally marketed, specifications of which are tabulated below:

| Constituent | Composition (wt%) | Stabilized | Un-stabilized |

|---|---|---|---|

| Purity | 98.2 | 99.2 min | |

| Ash Content | 1.0 max | 0.05 max | |

| Moisture | 0.3 max | 0.3 max | |

| Free Ammonia | 0.01 max | 0.01 max | |

| Chlorides | 0.001 max | 0.001 max | |

| Sulphates | 0.005 max | 0.005 max | |

| Heavy Metals | N.T. | N.T. |

Hexamine is used in: Rubber Industry, Explosives Industry, Fuel Industry, Synthetic Resin Industry, Pharmaceuticals, Photographic Industry, Organic Synthesis, Metal Industry, Leather Industry, Paper / Cellulose Industry, Lubricants Industry, and Fertiliser Industry.