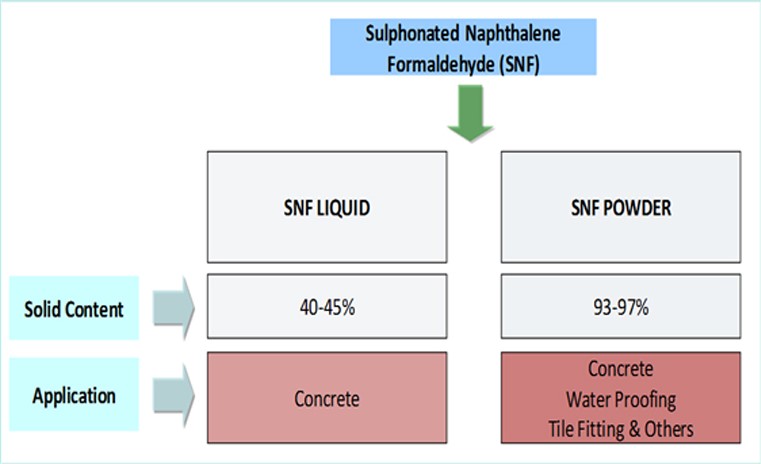

ATEC has developed highly effective water soluble superplasticizer additives for Concrete Admixtures. Complete design/engineering and technological Know-How is available for these Sulphonated Naphthalene Formaldehyde (SNF/PNS) based poly-condensation products for concrete application in liquid and powder form. Typical specifications are:

| Appearance | Clear brown liquid |

|---|---|

| Specific gravity @ 25°C | 1.19 – 1.24 |

| pH @ 25°C | 7 – 9 |

| Solids content (% by mass) | 40 – 42 |

| Dilution in water | In any ratio (dilutes rapidly in hard or soft water) |

| Sulfate content (% by mass) | 2 – 3 |

| Chlorides (ppm) | 250 max. |

| Miscibility with water | Miscible in all proportions |

| Shelf life @ 25°C | 1 year min. |

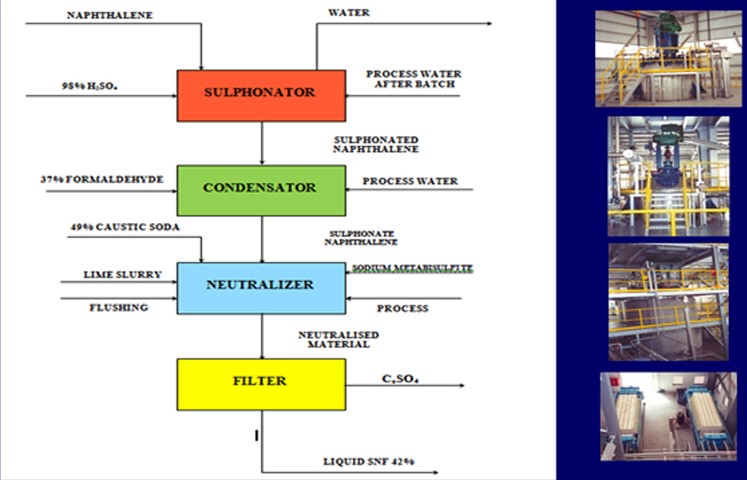

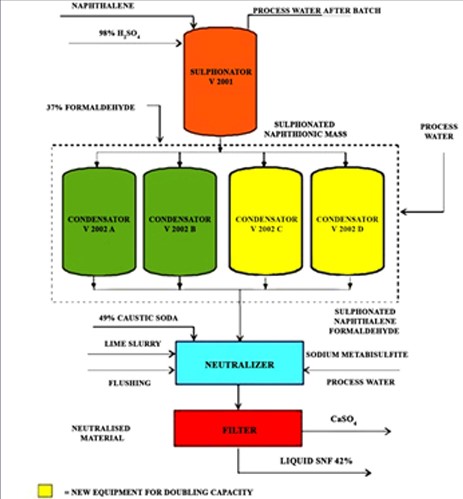

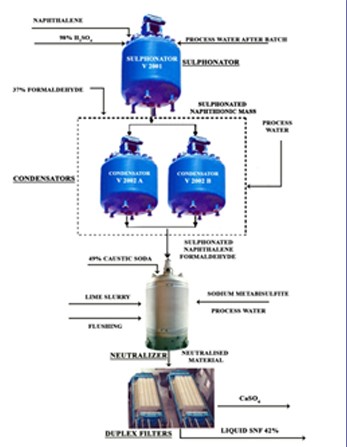

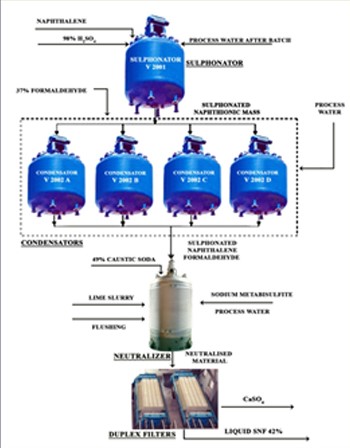

In ATEC’s process, three numbers of “Glass Lined Vessels” (One Sulphonator + Two Condensator reactors coupled to a common Neutraliser followed by a Duplex Filtration system) are employed in a single stream PLANT.

Adequate over plus capacity is provided in the design of key pieces of equipment to facilitate doubling of the PLANT capacity by addition of two numbers of additional Condensator Reactors.

An entire range of Sulphonated Naphthalene Formaldehyde Products for construction (Concrete additives), Leather Tanning, Dye Stuffs and Water Treatment applications can be produced in the same PLANT.

This is a unique “Modular Concept” evolved by ATEC, which enables easy capacity enhancement on most cost effective basis.

| Chemical Classification | : Sodium Salt of Polynaphthalene Sulphonic Acid |

|---|---|

| Appearance and Form | : Beige to Brownish free flowing powder |

| Solid Content | : 94 ± 1% |

| pH of 10% Solution | : 7 – 9 |

| Bulk Density (g/cc) | : 0.6 ± 0.02 |

| Ionic Nature | : Anionic |

| Solubility | : Soluble in water in all proportions |

ATEC has also developed extremely effective Melamine Formaldehyde Superplasticizers with the name ATM FORM 701 L / ATM FORM 701 P. These grades are aqueous Sulphonated Melamine based Synthetic Polymer, which in concrete displays powerful dispersion effect on both Cement and Pozzolanas. It forms a lubricating layer between the particles and thus lowers the internal friction between the Concrete components to yield better consistency, easy flowability, greater workability, fast and higher ultimate strength.

| Appearance | : Colourless to slightly yellow, transparent to slightly milky liquid |

|---|---|

| Specific gravity @ 25°C | : 1.255–1.265 |

| pH @ 25°C | : 8–10 |

| Viscosity @ 25°C CPS | : 30–60 |

| Solids content | : 40 ± 1% |

| Sulfate content (%) | : 1.75 max. |

| Chlorides (ppm) | : < 100 |

| Miscibility with water | : 6 months min. |

Polycarboxylates are high performance products for ready mix application...

| Characteristics | ATPOLY-40 G | ATPOLY-40 S |

|---|---|---|

| Solid content | 38–40% | 38–40% |

| Density | 1.06–1.12 | 1.06–1.12 |

| pH | 6.0–7.0 | 6.0–7.0 |

| Color | Clear amber | Clear amber |

Usage of ATPOLY – 40 G and ATPOLY – 40 S create a significant slump increase over time. A mixture of the two products can yield an optimal performance for any conditions. A mixture with 55% to 100% of ATPOLY Series is suggested.

ATPOLY – 40 G and ATPOLY – 40 S mixtures are normally dosed at 65 – 130 g per 100 kg (1 – 20 oz per 100 lbs) of cement. Other dosages may be required depending on specific conditions.

| TYPICAL PROPERTIES | |

|---|---|

| Chemical Classification | Modified Polycarboxylate Sodium Salt |

| Ionic Nature | Anionic |

| Chlorides (ppm) | Typical value <25 |

| Viscosity @ 25°C (cps) | Typical range 150 – 250 |

| Solubility | Dilutes rapidly in hard and soft water |