UREA FORMALDEHYDE CONCENTRATE (UFC-85)

ATEC possesses the complete technological Know-How to design / engineer plants to produce various Urea Formaldehyde Concentrate grades including UFC-70, UFC-80, and UFC-85 etc. Guarded proven know-how to produce Special UFC-85 grades for Urea Fertilizer conditioning / anti caking application is available. Process designs for UFC-85 capacities of (20 TPD – 200 TPD) are ATEC’s speciality.

Typical Product Composition:

| Constituent | Formula | Composition by wt.% |

|---|---|---|

| Formaldehyde | HCHO | 60.0 |

| Urea | NH2CONH2 | 25.0 |

| Methanol | CH3OH | 0.21 (max.) |

| Formic acid | HCOOH | 0.01 (max.) |

| Water | H2O | by balance |

| Chlorides | - | 0.001 (max.) |

| Iron | - | 0.0001 (max.) |

| Heavy metals | - | N.T. |

Major application areas of UF concentrates are conditioning / anticaking agent for Urea Fertilizer, Spray Coating Agent for Urea Fertilizer, Slow Release Fertilizer, Urea Formaldehyde liquid resins, UF powdered resins, UF moulding compounds, UF glues & adhesives.

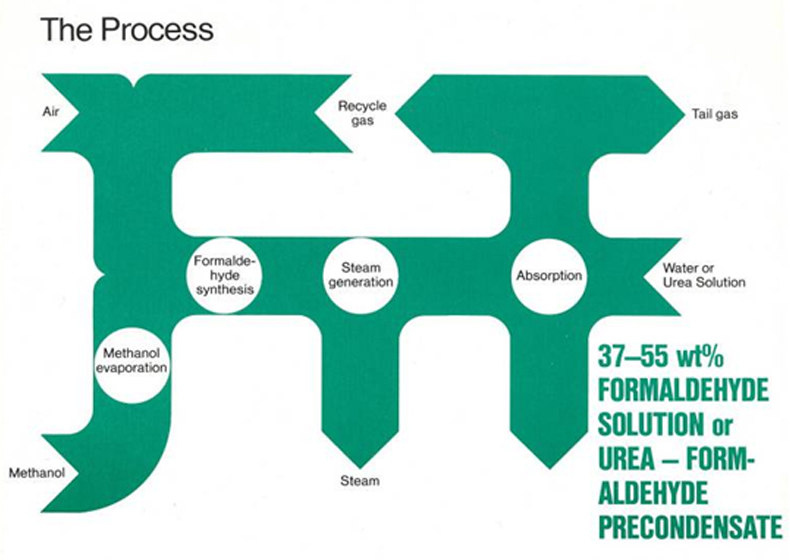

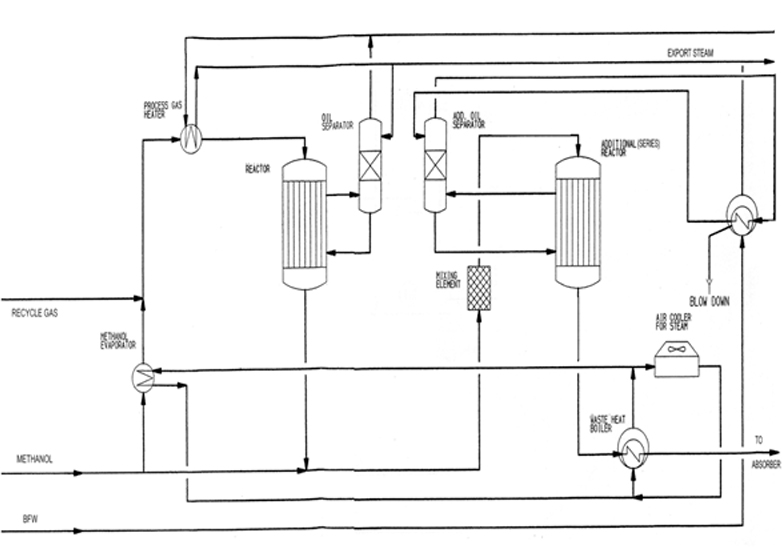

UNIQUE SERIES REACTOR SCHEME FOR AF37 / UF85 PRODUCTION

ATEC possesses the know-how for a unique Series Reactor Scheme in which the capacity of an excess air process-based Formaldehyde Plant can be increased with minimum investment.

By judicious incorporation of built-in over plus capacity (at initial stage itself) in key equipment section, the Plant Capacity can be doubled in a very short time frame, at half the cost by incorporating a “Series Reactor” in the process layout.

For example, by adding a ‘Series Reactor Scheme’ a 200 TPD Plant can be increased to 380 TPD at 50% of the original investment.

SALIENT FEATURES AND ADVANTAGES OF THE EXCESS AIR PROCESS

Salient Features:

- Faster plant installation

- Low raw material and utility input consumptions

- Higher conversion yield

- Fully automatic DCS based instrumentation

- No waste materials

The Advantages of the Excess Air Process Compared to the So-Called Excess Methanol Process Using a Silver Catalyst:

- The plant is easier to operate and is not very sensitive to power failures. It may be readily restarted after power failures lasting up to several hours.

- The yield is higher, typically 92–94% compared to 87.5% for the silver catalyst-based process.

- The Metal Oxide Catalyst is resistant to poisoning. Therefore, the quality demands for the Methanol feedstock and Air can be less stringent.

- A high Formaldehyde concentration (up to 55%) can easily be obtained without the use of auxiliary equipment, viz. a Concentration Unit.

- The Methanol content in the product is low, typically 0.41% by weight in AF37 and 0.21% by weight in UF-85.

- The process gives a large amount of export steam useful in other Process Units.

METAL OXIDE FORMALDEHYDE CATALYST

ATEC recommends to load the Formaldehyde Reactor tubes with the highly reactive & efficient Haldor Topsoe FK-2 Catalyst, which has a loaded density of 0.8 Kg. / Litre.

The typical lifetime of HTAS – FK2 Catalyst is above 33 months and Formaldehyde Production of upto 40 M.T. per Kg. of Catalyst. This is a rugged Catalyst capable of delivering high conversion efficiency on sustained basis over long periods.

Topsoe’s Formaldehyde catalyst is of the Iron-Molybdenum type in Raschig Ring Shape and is used in the Excess Air Process.

The catalyst is optimised for maximum yield and minimal pressure drop and is appropriately diluted in carefully recommended proportions with Porcelain Rings.

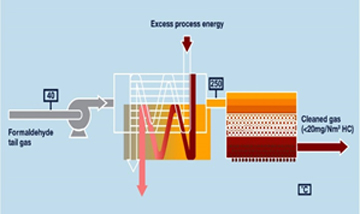

INCINERATION CATALYST

The catalytic incinerator will be loaded with Haldor Topsoe CK Catalyst. The typical lifetime of CK Catalyst is more than 4 years.

The off gases from the Formaldehyde Plants are led to integrated catalytic incineration units. Here the off-gas is preheated to 250ºC by heat exchange with surplus energy from the Formaldehyde process, before it is purified in the Catalytic Reactor and emitted to the atmosphere, as shown below :

The purification process results in a Formaldehyde emission below 5 mg/Nm³, while CO emissions are lowered to less than 20 mg/Nm³. As the purification is done at temperatures below 600ºC, the purification takes place without formation of NOx.

ATEC’s fully optimized process design affords completely environmental friendly Formaldehyde Plants capable of rendering “Zero Liquid Effluent Discharge” and statutory compliant “Ambient Emissions”.