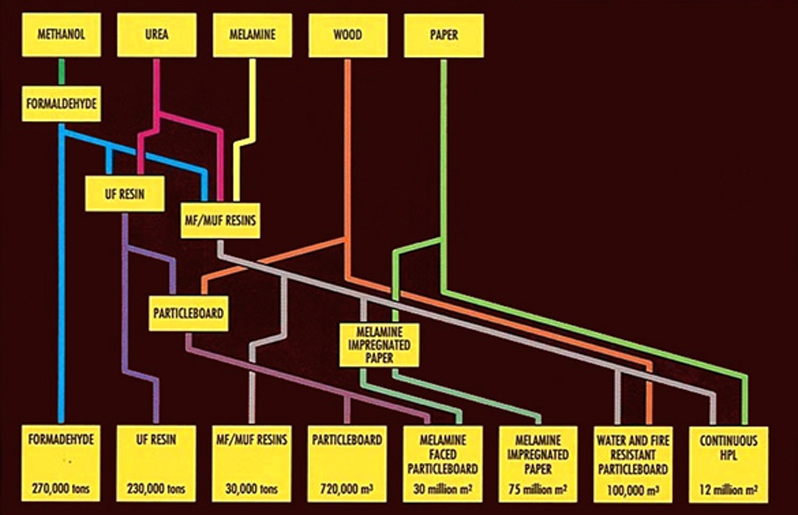

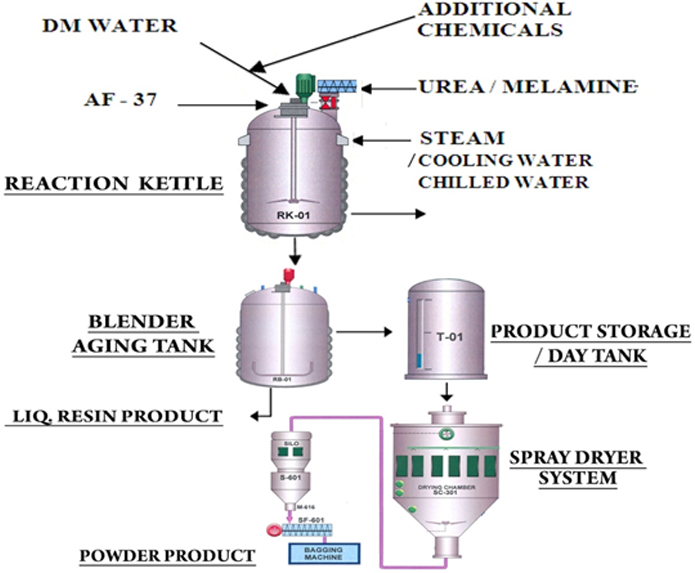

A block diagram showing a typical UF / MF / MUF Amino Resins manufacturing set-up is shown below:

UF / MF RESINS: BASIC PLANT CONFIGURATION & APPLICATIONS

UF / MF RESINS: BASIC PLANT CONFIGURATION & APPLICATIONS

(Liquid & Powder Grades)

ATEC has developed its own technologies with complete process know-how, design and engineering to manufacture various grades of UF Amino resins in both liquid and powder forms. The company offers its own special UF grades, viz.:

These are liquid and powder Urea Formaldehyde resins designed for plywood and veneering applications. Below are the typical specifications for ATUFORM 102P:

| Appearance | White free flowing powder |

|---|---|

| Viscosity (2 parts resin + 1 part Water) @25°C (Cps) | 2500 – 5500 |

| Viscosity (1 part resin + 1 part water) @25°C (Cps) | 180 ± 40 |

| pH of 50% Solution | 8 – 9 |

Products conforming to B.S. 6566 (M.R. Grade) can be made.

ATUFORM 103L / 103P

These are low formaldehyde emission liquid & powder

Urea Formaldehyde Resins for manufacture of MDF, Particle board and other cellulosic products.

Typical product specifications are:

| Appearance | White free flowing powder |

|---|---|

| Volatiles at 105°C/1hr (%) | < 3 |

| Viscosity of 60% solution at 25°C (cps) | 300 – 600 |

| Viscosity of 50% solution at 25°C (cps) | 100 – 200 |

| pH of 50% solution | 8 – 9 |

| Solubility | Easily soluble in water |

These are One-shot resins premixed with varying percentages of hardeners to suit specific application requirements. ATEC has tailor-made formulations for joinery and veneering application.

ATUFORM 102L / 102P AND ATUFORM 103L / 103P

ATMFORM 102 L / 102 P

ATEC has conducted extensive R&D work to develop and perfect numerous Melamine Formaldehyde Amino Resin formulations and owns the related technologies for manufacturing various liquid and powder resin grades. ATEC’s special Melamine Formaldehyde Resin grades are:

These are liquid and powder grades of unmodified MF resins ideal for impregnation of base/decorative papers and overlays in the production of HPL/CPL decorative laminates and low-pressure boards/panels.

| Appearance | White free flowing powder |

|---|---|

| Bulk Density (g/cc, min.) | 0.55 |

| Volatiles | 3 |

| pH (50% soln., 25°C) | 9.3 ± 0.7 |

| Viscosity | 30 ± 3 |

| Dilution in Water | Up to 25% solids |

| Gel Time (50% soln., @150°C) | 260 ± 20 seconds |

| Free Formaldehyde % | 0.6 ± 0.05 |

ATMFORM 103 L / 103 P

These are liquid and powder grades of precatalysed Melamine Formaldehyde Resin used for impregnation applications.

Typical specifications of ATMFORM 103 P Resin are:

| Appearance | White free flowing powder |

|---|---|

| Bulk Density (g/cc, min.) | 0.55 |

| Volatiles 105°C/1 hr. (%) | 3 |

| pH (50% soln.), 25°C | 8.8 ± 0.2 |

| Viscosity (50% soln., 25°C) cps | 30 ± 3 |

| Dilution in Water | Up to 25% solids |

| Water to Tolerance (50% soln.) % | 120 ± 20 |

| Gel Time (50% soln. @150°C) | 80 ± 10 sec |

| Free Formaldehyde % | 0.6 ± 0.05 |

ATMFORM 102 L/102 P and ATMFORM 103 L/103 P

Melamine Formaldehyde (MF) Amino Resins (Contd.)

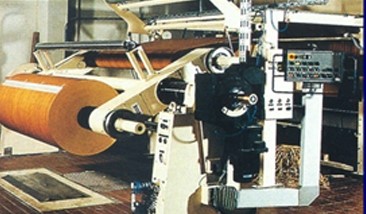

Application of Melamine Formaldehyde Resins

IMPREGNATION & DRYING

OF

PAPERS

FOR

DECORATIVE LAMINATES

Melamine Formaldehyde (MF) Amino Resins (Contd.)

ATMFORM 108 P is a powder Melamine Formaldehyde Resin used for glazing of Amino moulded articles viz. Melamine based crockery. The same resin can be used for the impregnation of overlay papers also. Basically ATMFORM 108 P is used in powder form for glazing application, while it needs to be reconstituted into solution form by dissolving in water for impregnation of papers. Typical specifications of powder (ATMFORM 108 P) are:

| Appearance | White free flowing powder |

|---|---|

| Bulk Density g/cc (minimum) | Min 0.400 |

| Free formaldehyde (%) | 0.600 ± 0.10 |

| Volatiles (105°C/1 hr) % | > 4 |

| Gel time at 150°C (seconds) | 25-45 |

| 50% Solutions Properties | |

| Appearance | Water white to slightly hazy liquid, free from suspended impurities and dissolved particles |

| Water tolerance | 50-120 |

| pH at 25°C | 7.4–8.4 |

| Viscosity at 25°C | 25–35 Cps |

ATEC’s ATMUFORM-108 Liquid and Powder Resins are specially developed Melamine modified Urea Formaldehyde (MUF) Resins synthesized with a Formaldehyde / Urea + Melamine @ molar ratio of 1.48. This Resin is particularly suitable as a plywood flooring adhesive. The MUF Resin is generally mixed with an extender, flour, and Ammonium Chloride.

Typical composition is as noted below:

| MUF Resins Solids | 39% |

|---|---|

| Total Solids | 55.8% |

| Water | 44.2% |

| Mixer Gel Time @ 100°C | 1.9 Minutes |

This resin is also used for Railway carriage and Marine container floors.

RESIN PROCESS BLOCK DIAGRAM

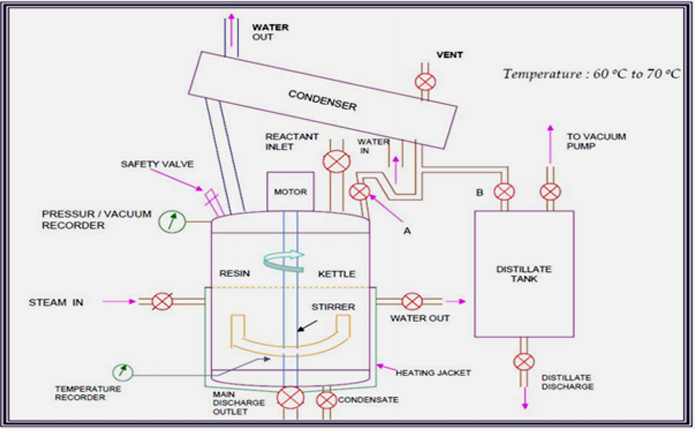

LIQUID UF / MF RESINS PLANT

UF RESINS PLANT (LIQUID SECTION)

MF LIQUID RESINS UNIT

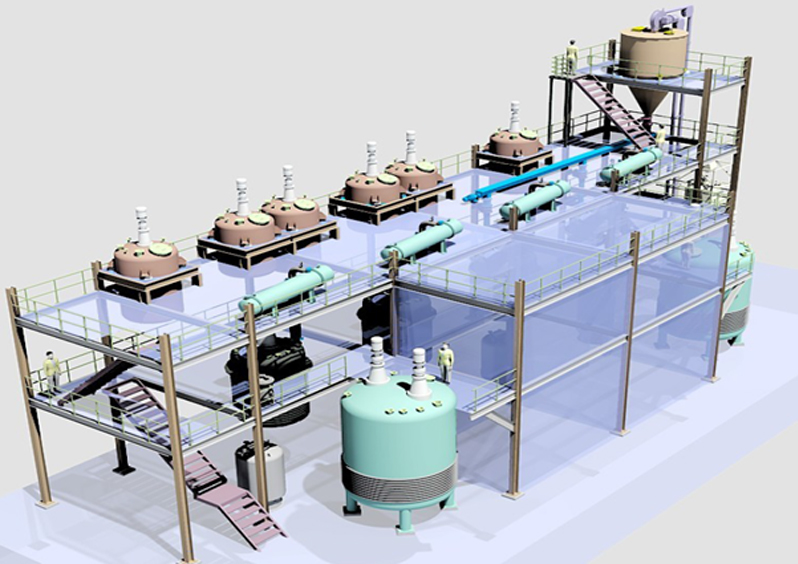

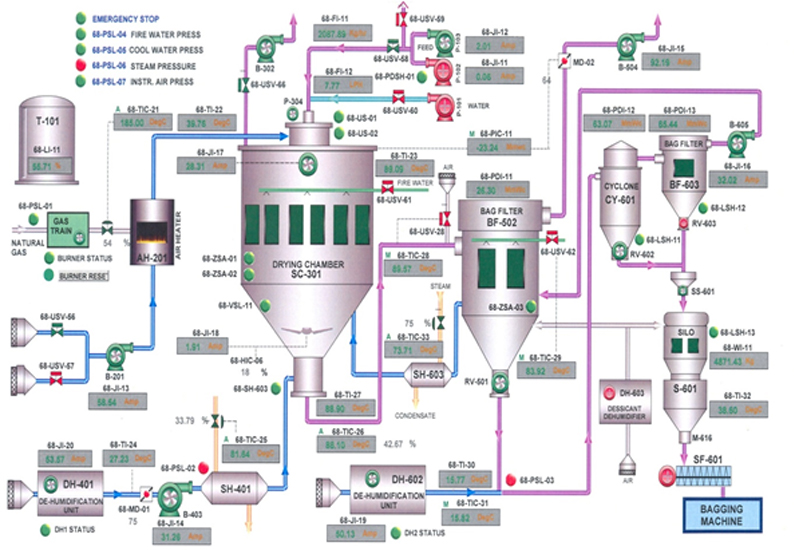

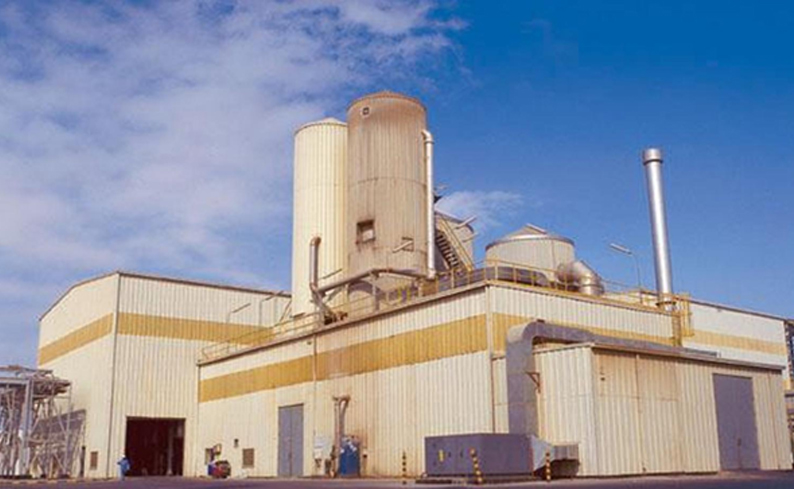

ATEC’s UF/ MF RESINS SPRAY DRYER TECHNOLOGY

Both conical and flat bottom Spray Dryer designs are offered with complete optimization of critical operating variables and parameters.

ATEC’s UF/ MF RESINS SPRAY DRYER TECHNOLOGY